Global Sourcing Capability Framework: Part 1

Global Sourcing Capability Framework: Part 1 – In this four part series, we examine eight dimensional capabilities.

In today’s post, we will focus on the two dimensions of cost and quality.

The myths surrounding global sourcing are many, widespread and often misleading. They usually revolve around business conducted in developing countries, the so called low cost country sourcing (LCCS) countries. LCCS is fertile ground for the politicians, humanitarians and environmentalist alike, covering misleading sound bites ranging from the export of jobs to the exploitation of child labour and the carbon footprint of the 3000 mile salad.

With the prospect of such reputation damaging headlines, it is critical for firms engaging in global sourcing to get their strategy right. This strategy must be supported by sound operational capabilities that not only manage the supply chain and the relationships within it, but that also make use of a well thought out communications strategy (should unwanted publicity arise).

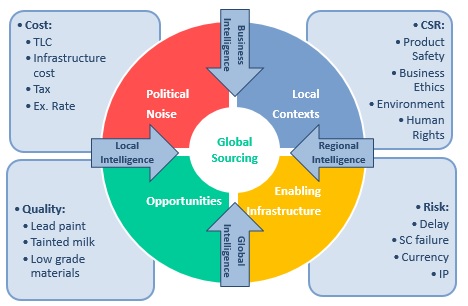

Purchasing Practice has developed a global sourcing framework (GSF) that incorporates these concerns into a logical management structure, and categorises them under eight dimensions:

The Eight Dimensions of the Global Sourcing Framework:

- Cost

- Quality

- Corporate Social Responsibility

- Risk

- Opportunities

- Politics

- Local Context

- Enabling Infrastructure

Dimension #1: Cost

Whilst costs are typically a primary driver of global sourcing, organisations must not only factor in total landed cost but also issues such as infrastructure cost and increased risk. This can include the cost of setting up a local office or hiring external auditors to monitor your suppliers in a particular country. Additionally, an upfront investment is frequently necessary in order to ensure the sourcing relationship is aligned with business goals and policy.

When these factors are quantified in a sourcing decision, the incremental savings from sourcing to a higher risk region or country are sometimes eliminated, especially when the principle benefit is labour arbitrage. However, many organisations are finding that the benefits of global sourcing still outweigh the investments if the right global partner is in place.

According to a Procurement Strategy Council report:

“Traditional models assessing the costs of global sourcing most often consider higher logistics and inventory costs due to longer supply chains, greater management costs to oversee remote and (often) unfamiliar supplier relationships, and higher taxes and duties. While these costs can reduce net savings by roughly half, emerging markets still provide a significant cost advantage of upwards of 25% savings.”

Traditional Model (based on industrial products example):

- labour savings 20-25%

- depreciation 5-10%

- materials and components 10-15%

- economic development incentives 0-5%

- savings on manufacturing cost (subtotal) 50%

- logistics, inventory costs -10-15%

- ongoing management costs -5-10%

- taxes and duties -0-5%

- net cost savings 25%

Procurement Strategy Council Model (factoring in hidden costs not considered in the traditional model):

- cost savings in traditional model 25%

- business partner non-participation -8%

- business partner non-compliance -6%

- savings (subtotal) 11%

- resource intensive sourcing activities -4-5%

- reputation risk exposure and mitigation -1-2%

- actual savings realized 4-6%

So whilst there are low cost countries, global sourcing will always be worthy of a buyer’s attention. Buyers should, however, be aware that the state of comparative cost advantage is dynamic, not static. This is true both within and between competing countries. Buyers must therefore possess the skills and motivations to monitor these dynamics as part of their overall sourcing strategy.

Dimension #2: Quality

Quality is usually a given in procurement organisations these days and is not ‘knowingly’ compromised for cost savings. Successful LCCS can deliver quality that is equal to, if not better than, local sources. This is in part achieved by working with suppliers to help them reach the desired quality standard prior to calling off production. When this is the case, it must be recognised as an additional cost of doing business and factored into sourcing decisions over the long term.

The key lies in putting in place all the right quality processes and checkpoints throughout the supply chain by qualifying inputs before they become embedded in products.

The increased risk of materials substitutions (i.e. lead paint and low grade materials) can also be driven by the refusal of Western buyers to allow suppliers to pass along cost increases which become amplified during a recession. So buyers must consider this when reviewing prices with suppliers.

Nuff said …

Part 2 will examine Corporate Social Responsibility in global sourcing.