A Guide to Global Sourcing for Competitive Advantage

A Guide to Global Sourcing for Competitive Advantage

A Guide to Global Sourcing for competitive advantage – A guide for CEO’s, CFO’s, and CPO’s, on how global sourcing can contribute to business objectives for sustainable competitive advantage

What’s in it for you?

Improved sourcing effectiveness and value from your supply base

Reading time:

15 minutes

1. Introduction:

Global sourcing has become an economic imperative for many organisations. Increased competition, globalisation, and the desire to enter developing markets overseas to drive growth have driven a greatly increased level of international sourcing. However, simply buying internationally is not going to provide the best solution to achieving the goals that will lead to continuing corporate success. A comprehensive global sourcing strategy is required.

Today, it’s no longer a question of whether a business should consider global sourcing; it’s a matter of ‘how’. How to launch, execute, and manage a global supply base to maximise benefits and minimise risks.

While cost reduction remains one of the leading factors in driving organisations to turn toward global sourcing, lower cost alone are unlikely to provide a competitive advantage if your competitors are also sourcing internationally.

2. Linking to Business Objectives

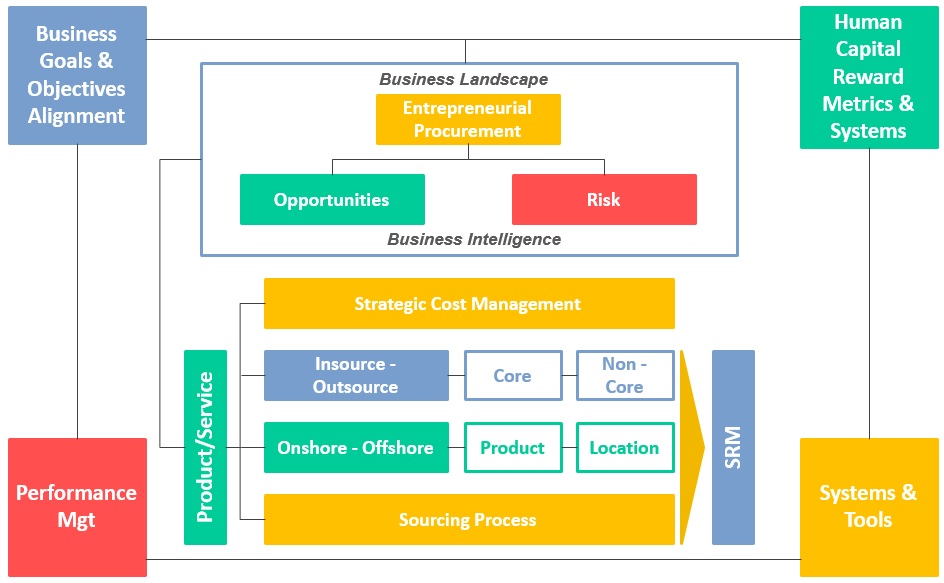

Global sourcing is one component of a company’s overall sourcing management strategy (Fig 1). It should systematically determine whether a product or service should be made in-house, outsourced, sourced locally, regionally or globally to support the organisations continued success.

In this context, clearly, a more strategic approach is required. One that effectively links global sourcing to the overall goals of the business.

Business goals that lead to sustainable competitive advantage (CA) include:

- Becoming the lowest cost producer

- Achieving world class quality

- Maintaining constant innovation

- Minimising time to market

When sourcing goals link directly to the business, global sourcing can make a significant contribution to the sustainable success of the business.

To do this procurement needs an evaluation framework (Fig 2) by to help them to understand their organisations business strategy, value chain and sources of CA in order to select appropriate products, locations and suppliers for global sourcing. Once this is understood, procurement can start to develop sourcing strategies that help strengthen existing sources of CA and secure new ones.

3. Process

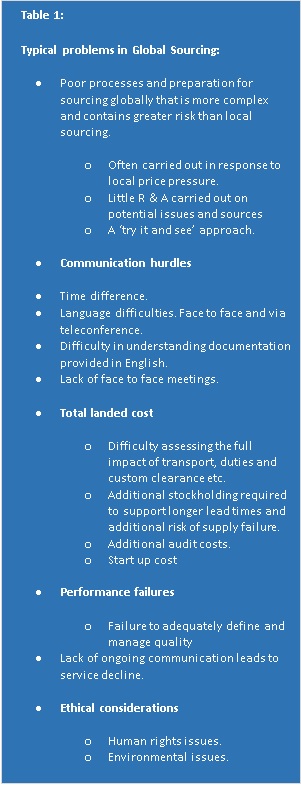

Many companies find the process of global sourcing, particularly in low-cost countries, extremely difficult due to the increased complexity. See Table 1. The truth is that failures in global sourcing activities expose the weakness of a company’s standard sourcing processes. A robust process by which to conduct global sourcing is critical.

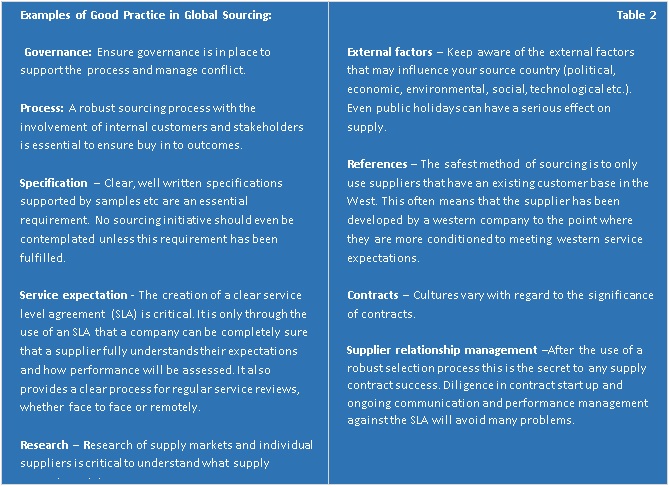

Commencing with the overall sourcing strategy framework and having reached the decision to source globally, the strategic sourcing process provides the discipline by which to manage supplier selection and to maximise value contribution.

Unfortunately, while many purchasing professionals will be able to show the ‘best practice’ chevrons for a successful strategic sourcing exercise. They will often admit to not practising such a robust process on a day to day basis. This lapse of discipline can result in problems later, particularly when sourcing globally as the supply base is often working to different standards of practice and acceptability concerning its local customer base.

The key to successful strategic sourcing is a robust and sustainable process supported by strong governance and conducted via suitably skilled people. See examples of good working practice in Table 2.

If you don’t reflect these disciplines in your strategic sourcing process, it will not be long before serious problems are uncounted. Once the sourcing process is complete ongoing supplier management is necessary to ensure quality, CSR and sourcing integrity are maintained and to protect against supply chain failures. This requires investment in time, resources and money.

4. Key Evaluation Dimensions

The key success factors of global sourcing evaluation revolve around three dimensions:

- product

- location

- supplier

These dimensions must be systematically evaluated as part of the strategic sourcing process:

4.1 Product

It is important to determine suitable products for global sourcing. The key is to target products that provide high benefit and low risk and that fit well with overall company objectives. Such products have high labour content and low shipping costs. A thorough product positioning review and business risk assessment should be weighed against the advantages taking into account factors such as product life-cycle, lead time, labour content, IP and transportation etc.:

- If a product requires 50% labour, it may make sense to source in countries that have low labour cost. If it only has 10% labour content, then it may make more sense to buy closer to home to save on transportation costs.

- Products that are large, bulky or perishable, are more difficult to transport.

- Products with large demand variation, require holding more inventory, increasing costs and risk of obsolescence.

- Products with long lead time may also increase inventory requirements.

From a supply chain perspective, you have to make sure that hidden costs don’t eat up the savings.

4.2 Location

Companies engaged in global sourcing should develop a geographic strategy to determine which countries they will buy from and how volumes will be allocated. By determining the comparative advantage of countries, procurement can determine whether it pays to source a product locally or internationally.

In addition to low labour cost, sources of comparative advantage come from factors such as:

- Available talent pool

- Cost of raw materials, capital equipment, and taxation levels, etc

- Logistics infrastructure such as roads and ports

- Political stability

Low wages doesn’t always mean low cost. If a country has a comparative disadvantage in any of these or other areas, it will reduce the benefit of low labour cost. Therefore, those countries with the right mix of macro-economic factors, infrastructure, and labor requirements represent the high potential countries for global sourcing. Labour cost must also be balanced against the required level of value added, the level of complexity involved in the production and the available skill levels.

Other considerations include the availability of banks, universities, insurance groups, public accountants, customs brokers, etc. to establish a robust local business network.

4.3 Supplier

A supplier profile should be developed, using an expanded version of your supplier questionnaire including extras, such as control of export documentation, etc.

A thorough knowledge of your suppliers is critical, to aid good communication. Due to the additional complexities of global sourcing it is advisable to allow for longer screening and trial periods with new suppliers to evaluate capabilities. Capabilities can be sub categorised, including:

- Current client-al and references in your market

- Quality assurance

- Employee hiring & training

- Facilities & Security

- Disaster recovery

- Process Capabilities

Part of finding the right supplier is ensuring that the organisation has more than just the right equipment and quality. It also makes sense to know whether the supplier can be a long-term partner with your business. To make such a determination it is vital to get a complete understanding of the underlying financial resources, management team, extended trading relationships and general management practices.

5. A Guide to Global Sourcing for competitive advantage

Conclusion:

Global Sourcing has become an economic necessity for many organisations with far reaching impact. The resulting extended supply chains, introduces increased lead times, additional touch points, ever-changing global regulations and increased risk. Sourcing globally may reduce cost but increases business complexity. To manage this increase in complexity businesses need to develop the new capabilities and metrics needed to administer and manage longer, more complex, riskier supply chains.

One of the benefits of working with a proven robust methodology is that it helps reduce the risks that can be associated with global sourcing. By rigorously tailoring the sourcing strategy to an individual product, country and supplier. Such a process speeds up the identification of opportunities and realisation of savings while addressing inherent risk.

Global sourcing can give companies leverage, and access to new intellectual capital and technologies far beyond what a domestic only supply network offers. Furthermore, input costs such as labour, land, overhead, raw materials, energy, employee benefits, etc. can vary significantly across regions, presenting a huge opportunity for those with the capabilities to execute.

Nuff said …